Recyclates stand for active resource conservation and sustainable industrial processes. They transform waste into usable secondary raw materials and close material cycles. This page concisely explains what recyclates are, how they are produced, what types there are – and why secondary raw materials are ecologically and economically convincing.

The focus is on the role of recycled materials in design, material selection and product life cycles: durable, easy to maintain, dismantlable and, ultimately, easily recyclable. This creates a well-thought-out circular model that reduces waste, emissions and energy consumption.

At Sedus, recycled materials are used to reduce the use of primary materials – and thus significantly reduce the ecological footprint of the products.

For products such as se:lounge or se:lounge light, we use PET felt, which is obtained from old PET bottles

What are recycled materials?

Recycled materials are materials that are obtained from used materials or production residues and used as secondary raw materials in new applications. In short, recycled materials are created through recycling, in which old materials such as plastics, metals, glass, paper or textiles are processed into usable raw materials.

Recyclates conserve primary raw materials, reduce energy consumption and lower CO₂ emissions. In comparison, the extraction of primary materials – such as crude oil for plastics or ores for steel – requires considerable effort. Recyclates are based on the idea of using existing materials in a resource-saving and predictable manner.

The recycling process in brief: Collection, sorting, processing. Metals are melted down, plastics are shredded, cleaned and made available as regranulate. Paper and cardboard fibres are processed into new fibre materials. This creates recycled materials that flow back into production as secondary raw materials.

Examples of recycled materials

- Plastic recycled material from PET for components and cover fabrics

- Recycled aluminium alloys for frames and profiles

- Steel from recycled materials for mechanisms

- Paper and cardboard recycled materials for packaging

PP recycled material (recycled polypropylene) is also widely used when robust, easily processable plastics are required.

Types of recycled materials and their properties

Recycled materials differ according to their origin and processing. The following is particularly important:

- Post-consumer recycled material (PCR): This comes from products that consumers have used, such as bottles, packaging or components.

- Advantage: direct waste avoidance.

- Challenge: fluctuating material purity, colour and composition. Careful sorting and quality-assured processing are crucial.

- Post-industrial recyclate (PIR): This is made from production residues such as punched grids or rejected parts. The material quality is often more homogeneous and the source is clearly documented. PIR is particularly suitable for technical components with high requirements in terms of stability and precision.

- Plastic recyclate in practice:

- PP recyclate offers a good combination of toughness, chemical resistance and processability. As regranulate, it can be used in a variety of ways – from housings to structural plastic parts.

How are recyclates produced? From waste to secondary raw material

High-quality recyclates are produced through coordinated processes. The aim is to produce reliable secondary raw materials from different source materials that meet technical, visual and health requirements.

Process steps:

- Collection and sorting by material type.

- Removal of impurities and cleaning of surfaces.

- Processing: metals are melted down, plastics are shredded, washed, extruded and processed into regranulate.

- Technologies for quality: Optical sorting, density sorting and colour recognition increase purity. Filtration and degassing during extrusion improve material quality. During compounding, additives and stabilisers are added to ensure mechanical properties, UV resistance and colour consistency.

- Challenges and solutions: Fluctuating material quality, impurities or colour differences are compensated for by strict specifications, traceability and testing. Tests on service life, emissions and safety ensure that recycled materials meet the standards. Where necessary, primary materials are added to optimise stability and appearance.

Design and quality principles for recycled materials

Recycled materials are particularly effective when products are designed for durability and recyclability. This includes modular concepts, separable material composites and easy-to-disassemble connections. These approaches facilitate repairs, extend service life and simplify recycling.

- Quality and safety: Recyclates must be resilient, compliant with standards and harmless to health. Mechanical stability, low VOC emissions, fire behaviour and colour fastness are crucial. For plastics, a defined regranulate with stable properties forms the basis for reproducible processes.

- Transparency: Clear information on origin, recycled content and recyclability builds trust and facilitates informed decisions along the supply chain. Documented secondary raw materials improve life cycle assessments and climate impact assessments.

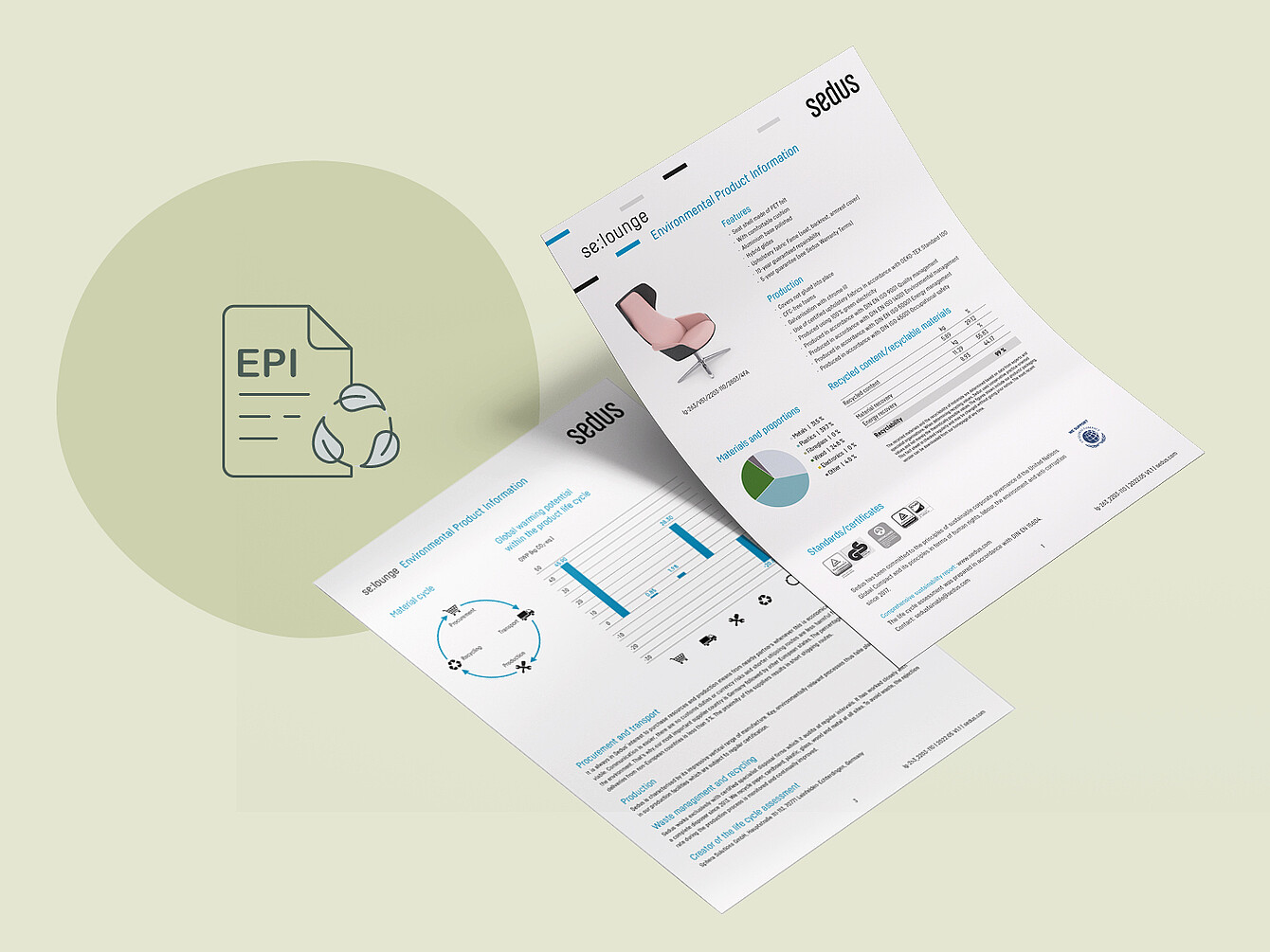

Clarity about the environmental impact of companies, products and processes forms the foundation of credible sustainability. At Sedus, this task is performed by Environmental Product Information (EPI). This environmental data sheet is available for download for over 100 products. It shows the emissions of each product and enables an informed analysis that drives targeted ecological improvements.

Environmental and economic advantages of recycled materials

Recyclates combine ecological advantages with economic sense. Every kilogram of secondary raw material replaces primary material and saves energy in extraction, transport and processing. This reduces the carbon footprint along the entire value chain.

Raw material security and resilience: Recyclates stabilise material costs and reduce dependence on fluctuating raw material markets. Clear quality standards and transparent information strengthen credibility and help to meet regulatory requirements.

Focus on plastics: Plastics decompose slowly in the environment and pollute ecosystems as microplastics. Plastic recyclates return waste streams to recycling cycles and conserve resources.

At Sedus, sustainability is not a trend, but part of our philosophy.

The use of recycled materials, green electricity, LED technology and heat pumps reduces the environmental impact. Sedus also attaches great importance to a sustainable supply chain and supports customers in using and disposing of products in a resource-efficient manner. The take-back and reuse programmes demonstrate the company's commitment to a functioning circular economy.

Read more about how Sedus lives sustainability

- How responsible materials shape the atmosphere, well-being and concentration in a room

- Sedus commits to Science Based Targets

- Sustainability at Sedus: circular economy as the key to conserving resources

- How does the Carbon Footprint Calculator work?

- The Eulenhof: a place for sustainability, community and sustainable agriculture

FAQ: Recycled materials – briefly explained

What are recycled materials used for?

For housings, frames, mechanisms, textiles and packaging. Examples: recycled plastic, recycled aluminium and steel, recycled paper.

What does post-industrial recycled material mean?

Material from production returns with homogeneous quality – ideal for technical components.

What does post-consumer recycled material mean?

Material from products that consumers have used. It reduces waste, but requires careful processing.

What is regranulate?

A granulate-shaped secondary raw material made from waste plastics.

What is recycled material?

A material obtained through recycling that serves as a secondary raw material in new products.

social media channels: